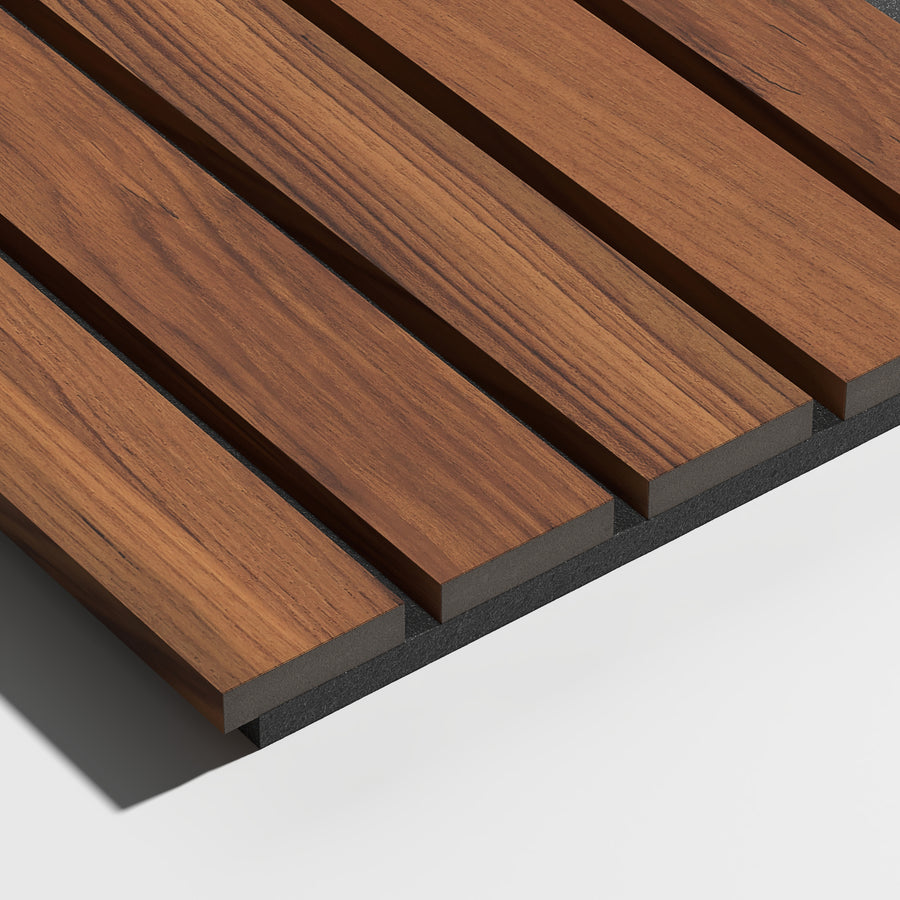

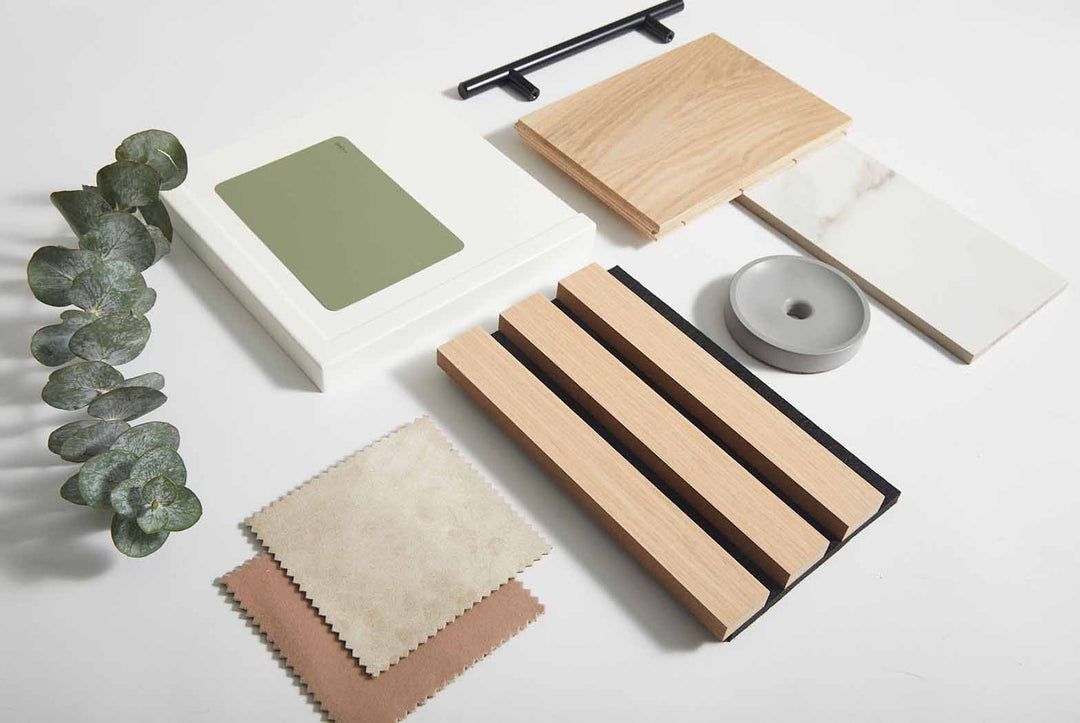

The Andor Willow Collection

Loved By Pros and DIYers Alike

Trusted By Clients of All Sizes

Let customers speak for us

Residential

From the living room to the bedroom and anywhere in between, our bespoke acoustic slat wood wall panel product line will instantly transform any space in your home.

Commercial

Our fast, expert service, artisan product quality, and reliable lead times are just a few of the reasons we're trusted by over 450 trade partners.

FULLY REFUNDABLE

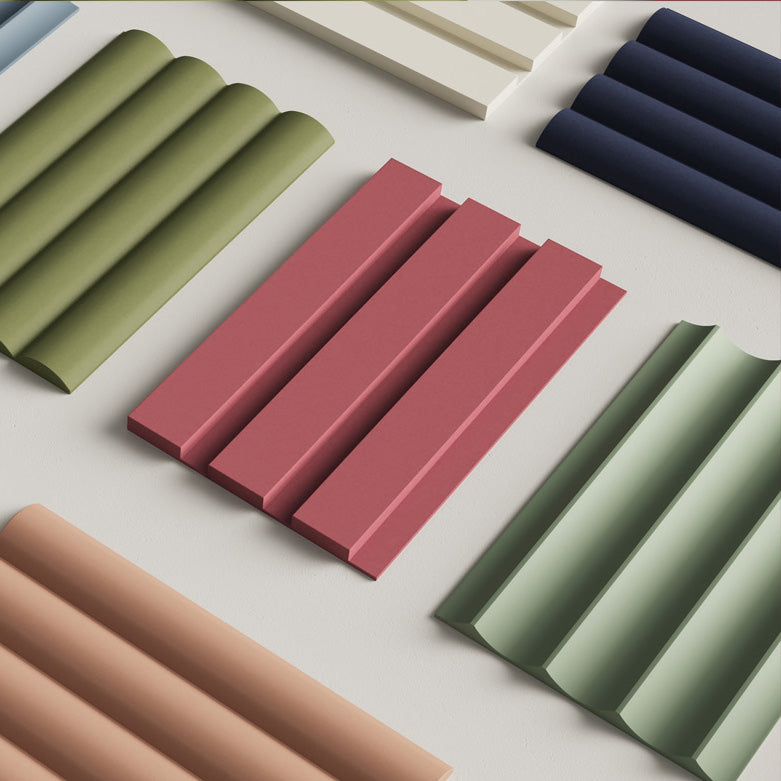

Order A Sample (or Three)

Order 3 samples, get the 4th free. Refundable samples of any of our exclusive product lines are available to order and ship in a matter of days.

Installs in Minutes

Whether you're a DIYer or you're working with a professional, our products are designed to reduce traditional installation times by 90%.