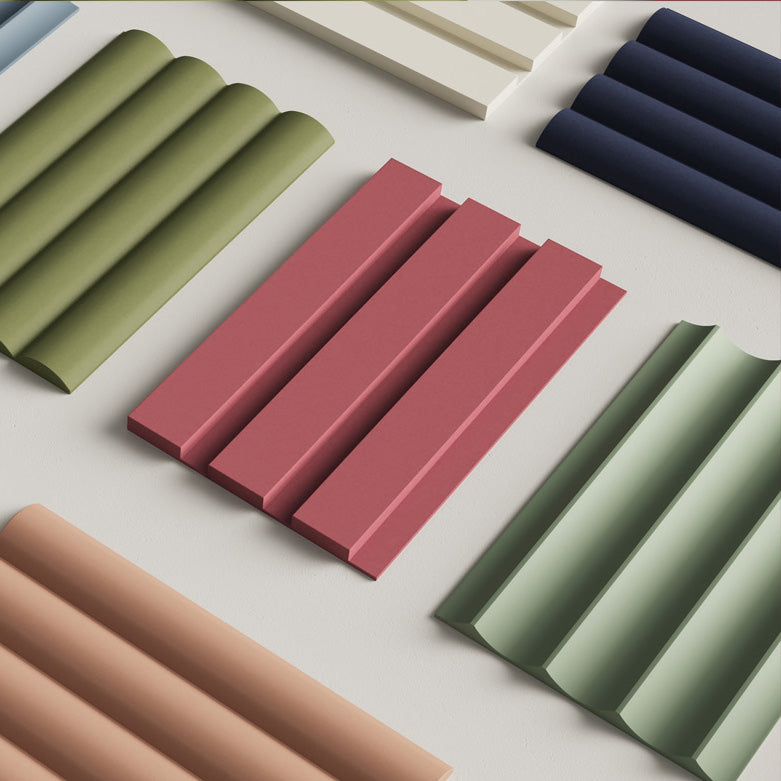

Tongue and Groove Wall Panels

Tongue and groove wall panels are a timeless way to add texture, depth, and architectural interest to a space. Whether used on a full feature wall, as wainscoting, or across ceilings and hallways, tongue and groove panels create a clean, intentional look that works across traditional, transitional, and modern interiors.

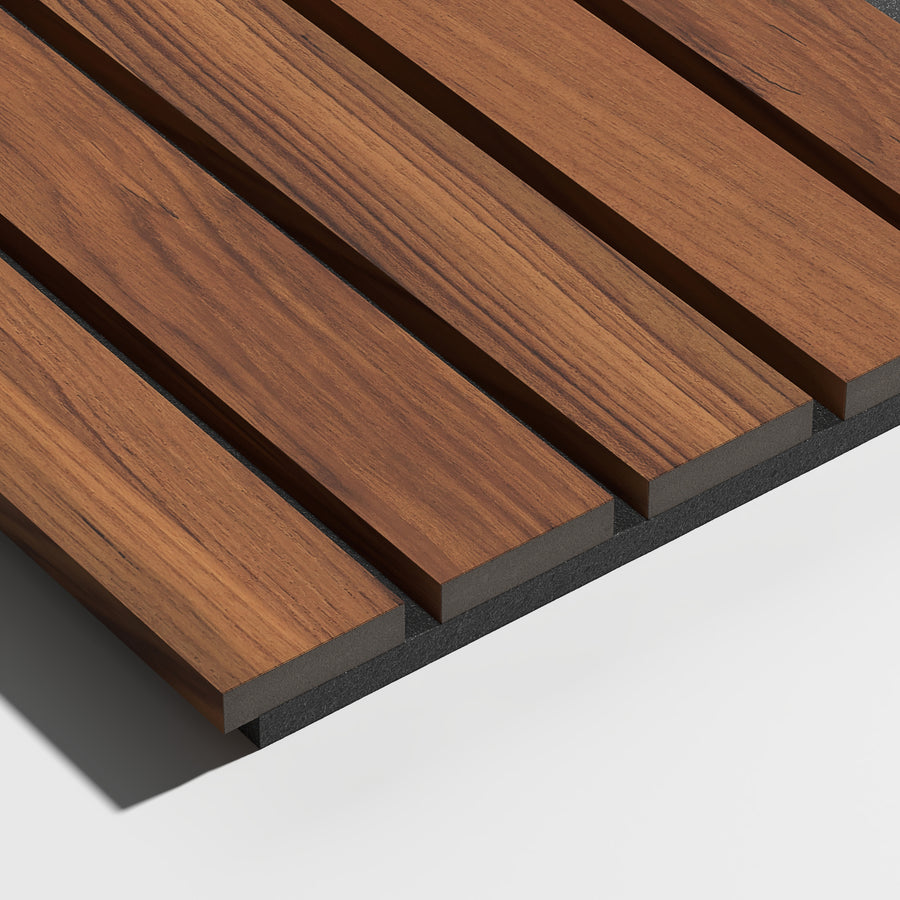

Our collection of tongue and groove panels includes both paintable MDF panels and real wood veneer panels, giving you flexibility depending on your design goals. Paintable T&G panels are ideal for custom color applications and classic millwork looks, while wood veneer T&G panels offer the warmth and depth of real hardwood with added dimensional stability.

All tongue and groove wall panels in this collection are designed for straightforward installation, consistent spacing, and long-term durability. Panels are available with 4 inch and 8 inch groove spacing and in lengths up to 9 feet, making them suitable for both residential and commercial applications.

Paintable and Wood Veneer T&G Panel Options

Paintable tongue and groove panels are made from premium MDF and come pre-primed for easy finishing. They are commonly used in bedrooms, living rooms, stairwells, mudrooms, and dining spaces where a crisp painted finish is desired.

Wood tongue and groove panels feature a genuine hardwood veneer over an MDF core. This construction provides the look of solid wood while improving stability and reducing the likelihood of warping or movement over time. These panels are pre-finished with a satin lacquer to protect the real wood surface, and reduce installation and prep time by over 50%.

Both options are designed to deliver consistent reveals and a refined finished appearance once installed.

Current Design Trends with Tongue and Groove Panels

Tongue and groove wall paneling continues to be popular in both new builds and renovations. Some of the most common trends include:

- Full-height tongue and groove panels to emphasize ceiling height

- Vertical T&G panels for a more modern, architectural feel

- Painted tongue and groove wainscoting paired with smooth upper walls

- Wood veneer T&G panels used sparingly as accent walls or built-in details

- Ceiling applications to add warmth and visual interest without overwhelming a space

Because tongue and groove panels are inherently simple in profile, they adapt well to changing styles and do not feel overly trend-driven.

Installation Overview

Tongue and groove panels can be installed directly over drywall, plaster, or plywood in most interior applications. Panels are typically fastened through the tongue so that fasteners are concealed once the next panel is installed.

Common installation methods include:

- Finish nails into studs or furring strips

- Brad nails combined with construction adhesive

- Screws in select commercial or high-traffic settings

The correct method depends on wall conditions, panel type, and local building requirements.

Tongue and Groove Panels FAQ

Can I put tongue and groove panels over drywall?

Yes. Tongue and groove wall panels can be installed directly over drywall as long as the wall surface is flat and secure. Fastening into studs is recommended for best results, especially for full-height installations.

Alternatively, battens (2x1 or 3x2 are typically suitable) can be installed on the wall with screws first, providing a stable anchor points for the panels to be nailed into with brad nails.

Should tongue and groove wall panels start at the top or bottom?

Most tongue and groove wall installations start at the bottom and work upward. This helps keep panels level and ensures consistent alignment as you move toward the ceiling. For ceiling applications, panels typically start along the longest straight edge.

How do you finish tongue and groove paneling?

Tongue and groove paneling is finished by sanding the panels as needed, applying paint or a wood finish, and sealing the surface for long-term durability.

Unfinished solid wood tongue and groove paneling, such as rough pine or cedar, should be sanded to approximately 100 to 150 grit, cleaned of dust, and then finished with a stain or clear top coat followed by a protective lacquer to preserve the wood and even out the surface.

Paintable MDF tongue and groove panels typically come pre-primed and don't require sanding before applying paint.

Pre-finished wood tongue and groove panels do not require any additional finishing, as they arrive ready to install, with final touch-ups usually limited to trim at the top and or bottom of the wall once installation is complete.

Does tongue and groove paneling increase home value?

Tongue and groove wall paneling can increase perceived home value by adding architectural detail and a custom feel. When installed cleanly and used thoughtfully, T&G panels are often viewed as a premium finish rather than a temporary design feature.

Do you nail or screw tongue and groove panels?

Most tongue and groove panels are installed using finish nails or brad nails through the tongue, using the "blind nailing" method. Screws may be used in certain commercial applications or when specified by local code, but they are usually concealed or countersunk.

How do you install tongue and groove wall paneling?

Tongue and groove wall paneling is installed by blind nailing the panels through the tongue into wall studs or pre-installed battens, starting with a level first panel and working panel by panel across the wall.

Studs are first located and marked, and battens are often added to create consistent fastening points when studs do not align with the panel layout. The first panel is leveled carefully, as it determines the alignment of the entire installation. Panels are secured using finish nails or brad nails driven at an angle through the tongue so fasteners are hidden once the next panel is locked in place (known as blind nailing). Expansion gaps are left at edges and corners to allow for movement, and these gaps are concealed with trim after installation is complete.

What are the pros and cons of tongue and groove panels?

Pros include a clean finished look, hidden fasteners, durability, and design flexibility. Considerations include installation time and material cost compared to drywall. Choosing MDF or wood veneer helps address many traditional concerns around movement and consistency.

Should you stagger tongue and groove boards?

Staggering seams is recommended when panels are installed horizontally to create a balanced appearance and avoid visible repeating joints. Vertical installations often use full-length panels for a cleaner look.

Is it cheaper to drywall or use tongue and groove panels?

Drywall is generally less expensive in raw material cost, but require professional installation/repair, as well as taping, sanding, and then painting. Tongue and groove panels cost more upfront but provide texture, depth, and a finished surface without the need for specialty installers or contractors.

Installing tongue and groove paneling is also much cleaner and less disruptive than drywall, which creates excessive dust and debris during installation.

What are common problems with tongue and groove paneling?

Common issues with tongue and groove paneling usually stem from material selection or installation practices. Solid wood tongue and groove panels can often include knots, cracks, and natural voids, which can be desirable in rustic applications but may feel inconsistent or low-grade in more refined interiors.

Many solid wood T&G panels are also sold rough-milled and installed as-is or painted without proper sanding and priming, which can result in an uneven, textured surface once finished.

Installation-related issues can include uneven walls, insufficient fastening, or failing to allow for seasonal wood movement. Using engineered cores like MDF or wood veneer panels and following proper installation and finishing guidelines helps minimize these issues and ensures a smoother, more consistent result.

What is cheaper, tongue and groove or shiplap?

Costs for tongue and groove panels vary primarily by material and construction rather than by the T&G profile itself.

MDF tongue and groove panels are the most affordable option and offer excellent consistency and stability for painted applications. Solid wood panels increase in cost as you move from pine to cedar to hardwoods like oak and walnut, with walnut typically sitting at the high end due to material rarity and finishing requirements.

Wood veneer tongue and groove panels, which pair a real hardwood face with an MDF core, usually fall between MDF and solid hardwood in price while offering improved dimensional stability and the appearance of natural wood. As a result, pricing differences are driven far more by material choice than by whether the panel is tongue and groove or another profile style.

Should I glue tongue and groove panels?

Construction adhesive can be used in combination with mechanical fasteners for added security, especially on uneven walls. Adhesive alone is suitable for wall installations, but nails and/or screws should be used to supplement adhesive in ceiling installations.

Can tongue and groove panels be installed vertically or horizontally?

Yes, tongue and groove panels can be installed either vertically or horizontally, depending on the desired look and the wall conditions. Vertical installations tend to emphasize ceiling height and feel more modern, while horizontal installations create a wider, more traditional appearance. In either orientation, proper fastening into studs or battens is essential to ensure a flat, secure installation.

Can tongue and groove paneling be used on ceilings?

Yes, tongue and groove paneling can be installed on ceilings, with a few important considerations. Panels should be installed perpendicular to the ceiling joists whenever possible to provide proper support. If joists do not run perpendicular to the panel direction, battens should be installed first to create solid anchor points. A combination of construction adhesive and brad nails is typically recommended for ceiling installations, and lighter, thinner panels are easier to handle and secure overhead.

Are tongue and groove panels suitable for bathrooms or humid spaces?

Primed MDF tongue and groove panels can be used in powder rooms or lightly humid spaces if all cut edges, seams, and exposed ends are sealed with a waterproof primer or sealant before installation, then painted and sealed with a water-resistant paint after installation. This method helps prevent moisture absorption but is not suitable for showers or areas with direct water exposure. Wood veneer tongue and groove panels are generally not recommended for humid environments, while solid wood paneling, particularly cedar, can perform well in humid spaces when properly finished and ventilated.

Do tongue and groove panels need acclimation before installation?

Yes, tongue and groove panels should be acclimated in the space where they will be installed. Panels are typically left in the room for 48 to 72 hours prior to installation so they can adjust to the temperature and humidity of the environment. Acclimation helps reduce the risk of expansion, contraction, or movement after installation, especially with solid wood products.

How much expansion gap should be left with tongue and groove paneling?

An expansion gap of approximately 1/4 inch is recommended at the top, bottom, and edges of tongue and groove paneling installations. This gap allows the material to expand and contract naturally with changes in humidity and temperature. Expansion gaps are later concealed with trim or molding to maintain a clean finished appearance.

Can tongue and groove panels be installed over plaster, concrete, or uneven walls?

Yes, tongue and groove panels can be installed over plaster, masonry, or uneven walls by installing battens first. Battens create a flat, level surface and provide consistent fastening points and run perpendicular to the panels. This method is especially common in older homes where walls are not perfectly straight and helps ensure a cleaner final result.

Are tongue and groove panels easy to remove or replace?

Tongue and groove panels are much easier to remove or replace when installed using battens and finish or brad nails rather than construction adhesive directly on drywall. Battens are typically fastened into studs with screws, and panels are then nailed into the battens instead of the wall itself. This approach minimizes drywall damage and allows panels to be removed or updated with significantly less repair work in the future.

Do tongue and groove panels work in modern interiors?

Yes, tongue and groove panels work very well in modern interiors when used thoughtfully. Vertical orientation, full-height installations, and knot-free, premium or natural finishes (like oak or walnut instead of knotty pine or cedar) help create a clean, architectural look. The simplicity of tongue and groove profiles allows them to complement modern spaces without feeling decorative or overly traditional.

How do tongue and groove panels compare to shiplap?

Tongue and groove panels create a tighter, more seamless surface than shiplap because the boards lock together and conceal gaps. Shiplap typically leaves visible shadow lines that feel more casual or rustic. Tongue and groove paneling is often preferred for applications where a refined, continuous finish is desired.

Are tongue and groove panels considered a permanent wall finish?

Yes, tongue and groove panels are generally considered a permanent wall finish. When installed properly, they add architectural detail and a custom feel that many homeowners view as an upgrade rather than a temporary treatment. However, using reversible installation methods like battens can provide flexibility and allow them to be renter-friendly without sacrificing durability or aesthetic appeal.

Don't just take our word for it

from 439 reviews

We are a general contractor and just finished a project using the wide willow oak panels. The project turned out incredible. The product is very nice and well made. I'm glad we found this product and company. We will definitely be using their products going forward on other projects.

It was my first project using Andor willow panels and it came out great! Took me two days total - one for building a frame around existing hood and gluing panels, and second for painting. Very easy to work with and looks beautiful!

We had a good experience with receiving and installing the product. Some of the edges of the veneer were (very) slightly damaged, but in my opinion, not enough to warrant a refund/replacement. With the help of a laser level, the install was quick and easy. I've added some photos. I've recommended the product to several friends already.

We installed this last year around October. We are very satisfied with the results. Our walls were longer so we added some modifications. Very good quality product.

I couldn’t be happier with these paintable ribbed wall panels! They were some of the most reasonably priced options I found online, and the quality exceeded my expectations. I hired a handyman to handle the installation, and after touching up the seams and the top of the wall with a little light caulking, the finished result was absolutely flawless.

The panels took paint beautifully, and the transformation they brought to my room is incredible. This feature wall has completely elevated the look of my space, and every time I walk into my house, I feel so excited and proud to see it!

The product is AWESOME! Nothing negative to say. We are still in the process of installing so I can add a “finished” photo then. But we love it!

We absolutely LOVE our wood slat room divider! Our living space is an awkward size, and this divider was the perfect addition to give the room dimension and a stylish touch while keeping everything feeling open and airy. It truly transforms the space and adds a lot of character. Guests always mention the slats when they see them for the first time.

The installation was straightforward if you're even a little handy, though we'd definitely recommend using a laser plumb bob to ensure everything lines up perfectly. It made the process much easier and more precise for us.

Also, the customer service was top notch. When we received the package, we had a small amount of missing hardware which was promptly taken care of for free.

Overall, a great product, and will definitely come back if we need to add more design details to our house.

This room divider has been an amesome addition to our living space. The high-quality wood and exceptional craftsmanship make it an eye-catching aesthetic centerpiece, elevating the entire room with its warm, modern appeal. Beyond its visual charm, it’s incredibly functional—providing just the right amount of privacy without making the space feel closed off. The durability is outstanding. It’s a perfect blend of style, functionality, and quality—highly recommend for anyone looking to enhance their home!

Relatively easy to cut and install. Getting the seams just right on corners was a challenge and hard to line up perfectly but overall the result is beautiful!

Excellent product. The install was exactly as described. And the product looks excellent in my space. Will serve well as a subtle room divider and privacy screen for occasional overnight guests.

Excellent customer service before and during the ordering and installation. Highly recommend.

Living room looks amazing

Love the panels- highly recomend

I specified a slatted design for a client water closet within the new bath. I ordered the two samples to review the wood and settled on the white oak. It perfectly matches the vanities I had built for the client. The product quality is fab. It was significantly less than custom building with my vanity woodworker. Client is thrilled. I’ll be using again on other projects.

Love the finished look!

We absolutely love our new wide willow panels. They look amazing!

The installation is straight forward, and delivery met our expectations.

The tall white oak wood with black felt panels worked great! They transformed and updated our living area. They even helped with the noise

level in the room. Installation was easy, we chose the glue method on the back of the felt panels. Very easy to install. We have had a lot of compliments.

Trusted by Businesses, Big and Small